The New Way Of Addressing Poor Print Registration From A Worn Out Feed Section

Front Wheel Improvements

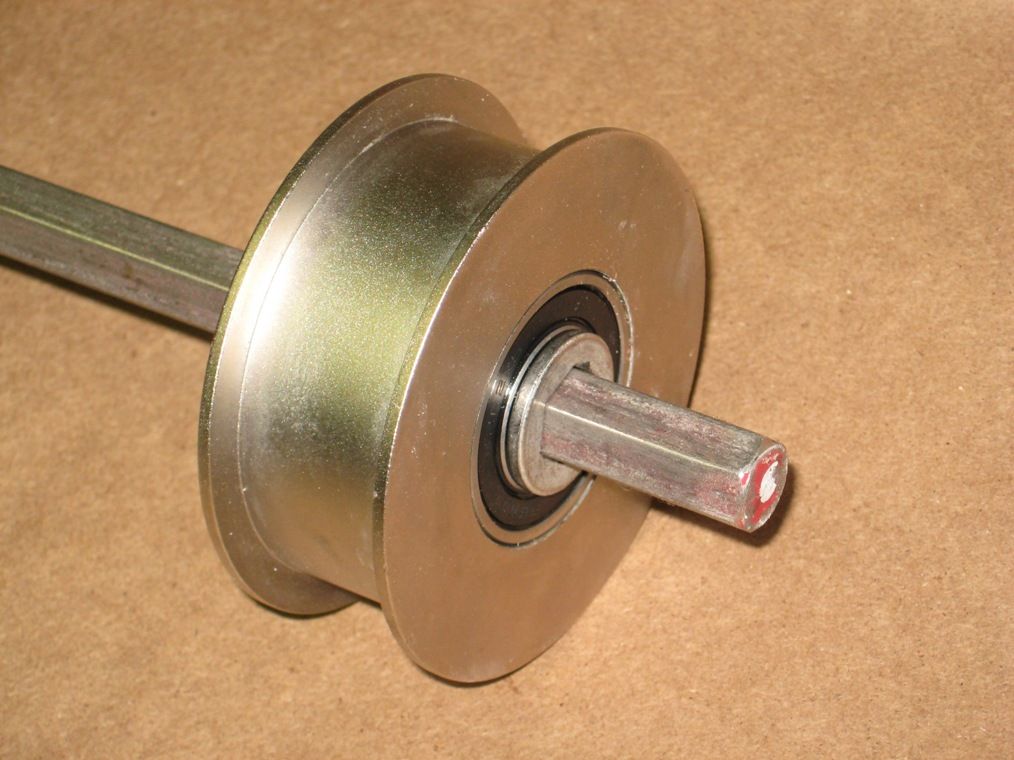

- Our Front Idler Wheels have two 6202 hex bore ball bearings installed in them instead of a plastic or bronze bushing. This adds longer life to the wheels and keeps wheels aligned with the belts.

- This improvement allows the use of replacing the original round shaft design with a hex shaft so that when the bronze or plastic bushing in the idler wheel wears, it damages the shaft and allows the wheels to cock sideways on the shaft which makes the feeder belt not track straight.

- This improvement also allows for the easy removal of the hex shaft from the wheels because the wheel bearings no longer rotate on the shaft, they rotate on the bearing hex adapters which are inexpensive and easily replaceable.

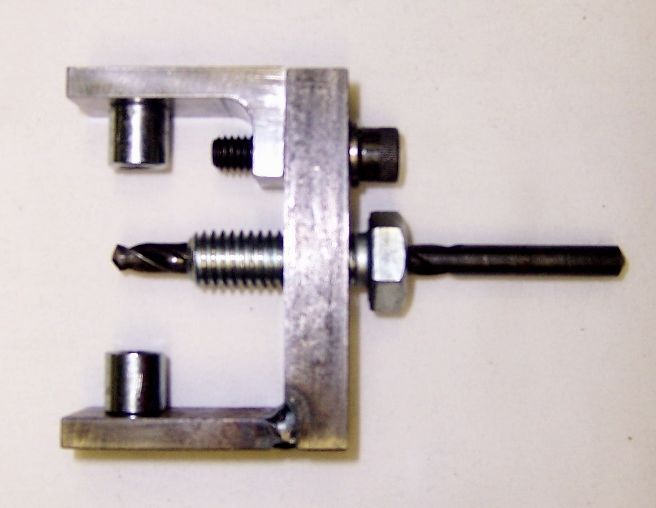

- To install this system the only modification to the machines is to drill and tap sixteen 5/16” holes in the vacuum table front shaft supports. This locks the hex shaft into position so there is no longer any spinning of the whole front shaft if a bearing or bushing in one of the wheels lockup damaging the vacuum box supports bores as seen sometimes with the original round shaft design. We supply a drill jig to complete this modification.

- We also supply a coupling which joins the two hex shafts together in the middle to support the ends of the two center wheels next to the gearbox. The original design has no support for the ends of their shaft which allows the shaft to bend and the wheels to run out of alignment when the belt tension is applied.

- Our lightweight belt drive pulleys are machined with a long hub which accepts a 5/16” keyway 2 ¼” long and utilizes two locking screws to hold them in place. This eliminates loose fitting gears that result in print register problems. The original design uses plastic keyways with no locking screws which causes loose gears.

- We replace the belt pulley drive shaft gear with a special modified gear in the feeder gearbox to enable us to install a shrink disc system that locks the feeder belt pulley drive shaft to the special modified drive gear without the need for keyways. This eliminates the drive shaft from coming loose inside the drive gear which also affects print register and eliminates the need to replace shaft and gear in the future because of keyway wear. This modification allows for the use of two easily installed belt pulley drive shafts instead of one long shaft that has to be installed all the way through the gear with double keyways which have to be hand fitted between the shaft and gear with nothing locking them in place.

- The modified gear upgrade comes with all new bearings, locking nuts and locking washers, keyways, set screws, and shafts.

Belt Tension Bracket Improvements

- We replace all 16 of the original tension brackets with newly designed brackets.

- The new brackets are laser cut and then heliarc welded in a fixture to insure the layout of all the holes are the same.

- They utilize split collars to clamp the idler wheel axles in place to eliminate any looseness that would affect feeder belt tracking or the axle spinning that would cause damage to the bracket itself.

- The bracket has replaceable bushings which slide on the original shoulder bolts. If the threaded holes for the shoulder bolts are worn or damaged in your machine, we supply a repair kit with a drill and tap fixture for inserting threaded inserts

- The new brackets also utilize a specially machined Linear bearing with O-rings and linear bearing shafting to hold the Idler tension pulley in line.

- These brackets do not require any modification to your machine. Simply remove the original tensioning spring and use the supplied flex-hone to deburr the bore. Then slip this new bearing in and lock in place with a set screw in one of the tapped holes formerly used for the jib plate.

- We supply new tensioning springs which are inserted inside the linear shafting and with an O-Ring in the Linear bushing the system is sealed and can be permanently lubricated at installation.

- Tensioning idler wheels have two 6202 ball bearings installed in them instead of bushings. This adds longer life and keeps wheels aligned.

- They also come assembled with a ground and hardened axle.

- All of our idler wheels and drive pulleys are precision CNC machined from 6061 aluminum.

- Next they are sent through a Hard Coat process to extend their wear life.

- They are also Teflon Coated to reduce build up of paper dust.

Idler Gear Upgrade for 37” Ward

If you have the older model 37 1/2” Ward Belt Lead Edge Feeder, you need this item. This is a relatively simple fix at a very reasonable price compared to the price you will eventually be forced to pay without it!

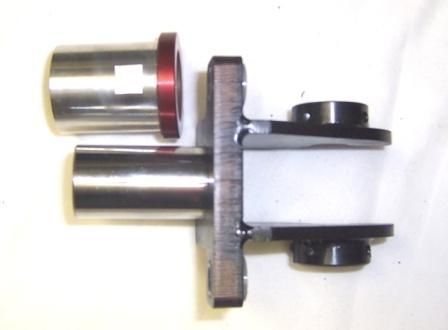

Your center gear box idler gear rotates on a cam follower. This assembly is supported by a small shaft that is not sufficient to handle the task and commonly fails or breaks. When the idler gear support shaft does break, the damage can be mild to catastrophic. It will jam the gear train and it often completely destroys the center gear box by splitting the gearbox housing itself. This can cost upwards of $50,000 to replace.

The idler gear upgrade prevents this from happening. It has a much larger support shaft with Timken roller bearings supporting the idler gear. This upgrade is a much more reliable improvement over the small support shaft originally designed for this machine. Preventative maintenance should be a requirement in this case to prevent the possibility of a drastic unexpected expense. QuickFab’s Idler Gear Upgrade is comparable to the OEM, however we are able to offer it at a more competitive price.

Top Wear Strips

Our Lead Edge Feeder Top Wear strips are machined from stainless steel and then are case hardened through and through. This process extends the wear life considerably over the competitors that hard surface plate 2 or 3 thousandth over a softer metal body. Wear strips should be changed when they’re worn .018-.020 for ideal print registration and belt life. Any new wear strip should measure. 437 thick.

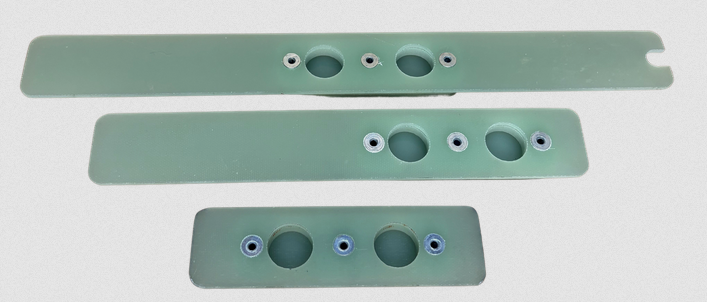

Vacuum Block Off Plates

Our Vacuum Block Off Plates are made from Garolite, a high strength material, and we are able to offer them at a very reasonable price.

Lead Edge Feeder Cam Shaft Kit

QuickFab’s Lead Edge Feeder Cam Shaft is comparable to Ward’s Part #135842. We offer the whole kit or individual parts for the 37 ½” LEF Cam Shaft Assembly which includes all seals, bearings, the universal, and the wear ring. Compare pricing and then give us a call!

Cam Shaft Drive Ringfedered Coupling

When the output shaft of the Camco box has some wear, you probably try to install a new OEM coupling and tighten the allen screws that are supposed to lock it down. Most likely it can never be tightened enough to work, so you replace the whole box. Not anymore!

The coupling we make allows you to still drive the cam shaft without replacing the Camco box. Because ours has a ringfeder, it tightens down enough that you can still run and it lasts much longer than the factory options. Save time, save money, and save your Camco box with our ringfedered coupling

Index Drive Shaft Coupling and Camco Gear Box Input Drive Coupling

Similar to the Cam Shaft Drive Coupling we offer, upgrading your index drive shaft coupling means changing from the keyway style to a ringfedered style coupling. We take a steel coupling and put in special ringfeders which eliminates the problem associated with a keyway fit. This style coupling will also replace the Camco gear box input drive coupling.

We also offer the Camco Gear Box Input Drive Coupling with the flex style center with shrink disk style locking mechanism.

Product Information

Top Wear Strips

LEF-163735 Ward Wear Plates- 37”/50”

LEF-146327 Ward Wear Plates- 50”/66”

LEF-258746 Ward Wear Plates- Extended Feed

Vacuum Block Off Plates

LEF-VBP-S Ward Vacuum Block Off Plates- 153235

LEF-VBP-L Ward Vacuum Block Off Plates- 146320

Lead Edge Feeder Cam Shaft Kit

LEF900 LEF Cam Shaft Kit

Cam Shaft Drive Ringfedered Coupling

SDC003 Cam Shaft Drive Ringfedered Coupling

Index Drive Shaft Coupling and Camco Gear Box Input Drive Coupling

LEF-178275 Camco Input Drive Coupling (Flex)

LEF-A129263 Camco Input Drive Coupling (Rigid)