Can your operator replace your pump in 60 seconds without any tools or training?

They can with our Quick Change Pump System!

Our Quick Change Pump System is an air diaphragm pump with a remotely mounted air valve that is speed controlled by an electronic control panel. It is available for either single or dual pump systems

- One pump fits all… means less inventory. All supply and return pumps are the same and are interchangeable between various print systems within your facility.

- No messy lines to disconnect. They stay connected to the manifold.

- Non corrosive modular design. All stainless steel and plastic construction.

- Pump rebuilds are simple and economical. Our pump rebuild kits have few parts and need no special tools or skills to master. Anyone can successfully rebuild a pump with less than 10 minutes of training.

Your first Conversion Set includes the applicable Quick Change Pump manifold, Quick Change Pump(s) for each section, an additional “spare” pump, appropriate mac valves, an electronic control panel where applicable, and an assembly jig. As you continue to convert print sections throughout your facility, QuickFab, Inc. offers additional conversion sets based on your needs. Quick Change Pumps and parts are also offered individually.

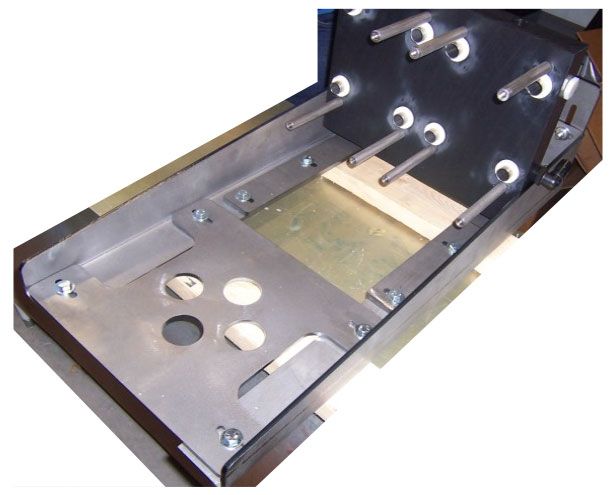

Ink Bucket Trays

Our modular stainless steel tray systems replace your old OEM trays with an all stainless, easy to bolt together design which supports the pumps and ink bucket. It assembles in just a few minutes with hand tools. The machine mounting plate is made from 3/8” steel with assorted holes which can be drilled or slotted to fit your particular machine if needed.

Ink Filters

If you are not using ink filters, why not? Is it because the filters that typically come in machines get clogged too quickly causing the machine to run out of ink and shut down, or were you having to clean them way too often so you just pulled them off?

Instead of the filter fitted at the beginning of the supply source we recommend that you hang the filter inside the bucket and put your return line in the filter. This way all of the contaminants that are coming from the machine’s print system collect in the filter which prohibits it from getting back into the supply pump and therefore through the print system again. The cycle of continuous and compounding debris is greatly reduced compared to using no filter at all.

So why is the QuickFab filter better than other bucket filters in the market? Other ink bucket filters have no framework, no corrugation, are not completely sealed but only tacked together. They are simply flimsy. QuickFab ink filter construction begins with a stainless steel framework. We then insert stainless steel corrugated wire mesh sides and bottom. We spot weld them into place and then completely seal them to the framework. This produces more durability with more surface area in the same size filter as the more expensive option, with better effectiveness. We have also worked through the process of determining the ideal mesh size for a 40,000 box run average before cleaning is necessary. This also provides longer run times between cleaning.

Ink Bucket Lids

To keep your work area cleaner and to help reduce debris from contaminating your ink, we offer a lid for your ink buckets that make using them simpler. Our stainless steel lids are hinged for ease in removing and replacing ink filters or hoses. They also come with 3 holes and bulkhead fittings and plugs that you can adjust to fit your application.

Heavy Duty Duckbills

We manufacture our own custom designed heavy duty duckbill valves from Nitrile—a durable material that works with all inks and clean up solutions. Our large duckbills can pass small trim and debris that may have found its way into the ink system. They can be cleaned or replaced without tools and without removing the pump. Simply lift the end cap off the pumps and replace after inspection. With our system, duckbills can not be installed backwards.

Product Information

Ink Filter

QFIF001 Ink Filter

IBL001 Ink Bucket Lid

Heavy Duty Duckbills

QCP024 Duck Bills